The methanol fuel cell

HT PEM fuel cell stack

Blue World Technologies’ high-efficiency fuel cell stack is available in several variants enabling high system power density

Methanol fuel cell stack

The high-temperature PEM (proton exchange membrane) fuel cell technology, which enables the Power-to-X eco-system, helps to address aspects of the green transition that cannot be solved by direct electrification and battery technology alone.

Blue World Technologies’ high-efficiency fuel cell stack is available in 9kW and 18kW variants with market-leading energy density.

Key features

Integrated evaporator

Tailored for steam reforming integration, this component not only simplifies the methanol evaporation process but also significantly cuts down on energy consumption. It's a dual-purpose innovation that enhances overall efficiency, making our fuel cell stack a sustainable and resource-efficient solution for a variety of applications.

High CO tolerance

The fuel cell stack can accept a higher concentrations of carbon monoxide of 1-3%. This enables a very simple and cost-efficient total system design without purification of the reformate gas.

Simple efficient cooling

The fuel cell stack operates at 160-180°C and is liquid cooled which enables a simple cooling system due to the relatively high temperature difference. Both the size of the cooling system and the parasitic power losses for running fans, among other things, are significantly reduced compared to other types of PEM fuel cells.

Optimised Waste Heat Utilisation

The 160-180°C liquid cooling medium enables use of the high value waste heat for various applications beyond what is known today from internal combustion and other types of PEM fuel cells.

Air pollution reduction

Our methanol fuel cells reduce NOx, SOx, and particle emission. Thereby contribute to defeating air pollution.

Reduced BOP components

The HT PEM fuel cell stack requires less Balance of Plant (BoP) components compared to similar PEM technologies. The HT PEM technology eliminates the need for Cell Voltage Monitoring (CVM) and humidification processes. This enhances overall efficiency but also reduces maintenance requirements, making the Blue World stack a cost-effective solution in a total system design.

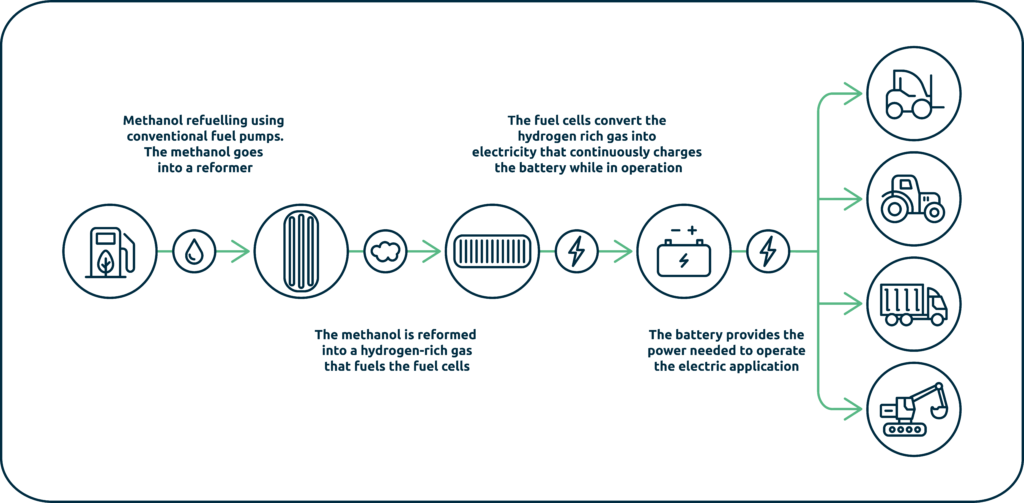

The principal of a Blue World fuel cell platform integrated into varoius electric applications

Download

Download the datasheet for more detailed technical specifications

Sales and service offerings

Our commitment to sustainable energy solutions is reflected in our innovative fuel cell stack offerings, designed to empower system integrators and corporate partners. Explore our three distinct sales models:

Direct stack sales

Selling standard high efficiency fuel cell stacks for experienced system integrators available in 9kW and 18kW variants.

Corporate partnerships

Engagement in corporate partnerships where Blue World Technologies enables partners to design their own system for a specific application. Supporting with both stacks and system for them to become integrators.

Eco-system

Enabling fuel logistics and fuel supply. Blue World Technologies assists with knowledge of renewable methanol supply.

Sales process description

Equipment Sales

Includes the fuel cell stack and methanol fuel reformer + basic documentation and user manual.

Equipment Sales+

Comprehensive package that encompasses proof-of-concept/demo, engineering services and support (including documentation such as P&ID and schematics, consultancy services, and BoM information), as well as Equipment Sales.

Introduction

The process begins with preliminary dialogue with customers, followed by clarification of product details and requirements, and then initial technical discussions.

Contracting

Submitting a formal tender or request for proposal, providing system engineering support to the customer, and offering comprehensive engineering support, including items outlined in Equipment Sales+.

Proof-of-concept/demo

Demonstrating product qualifications through single-system trials or demonstration projects during a trials period is essential.

Scalable equipment sales

Upon successful engineering and PoC/demos equipment sales are initiated.

Want to know more?

Our team is ready to provide you with further information on pricing, availability and the use of methanol fuel cell technology for different applications or within specific industries.

Working at Blue World you will make a difference – for the company, your colleagues, and for the world

The methanol fuel cells provide high energy-efficiency and long lasting durability

The methanol fuel cells act as a green alternative to a wide range of industries around the world