The fuel cell technology

A strong technology platform

State-of-the-art methanol fuel cell technology

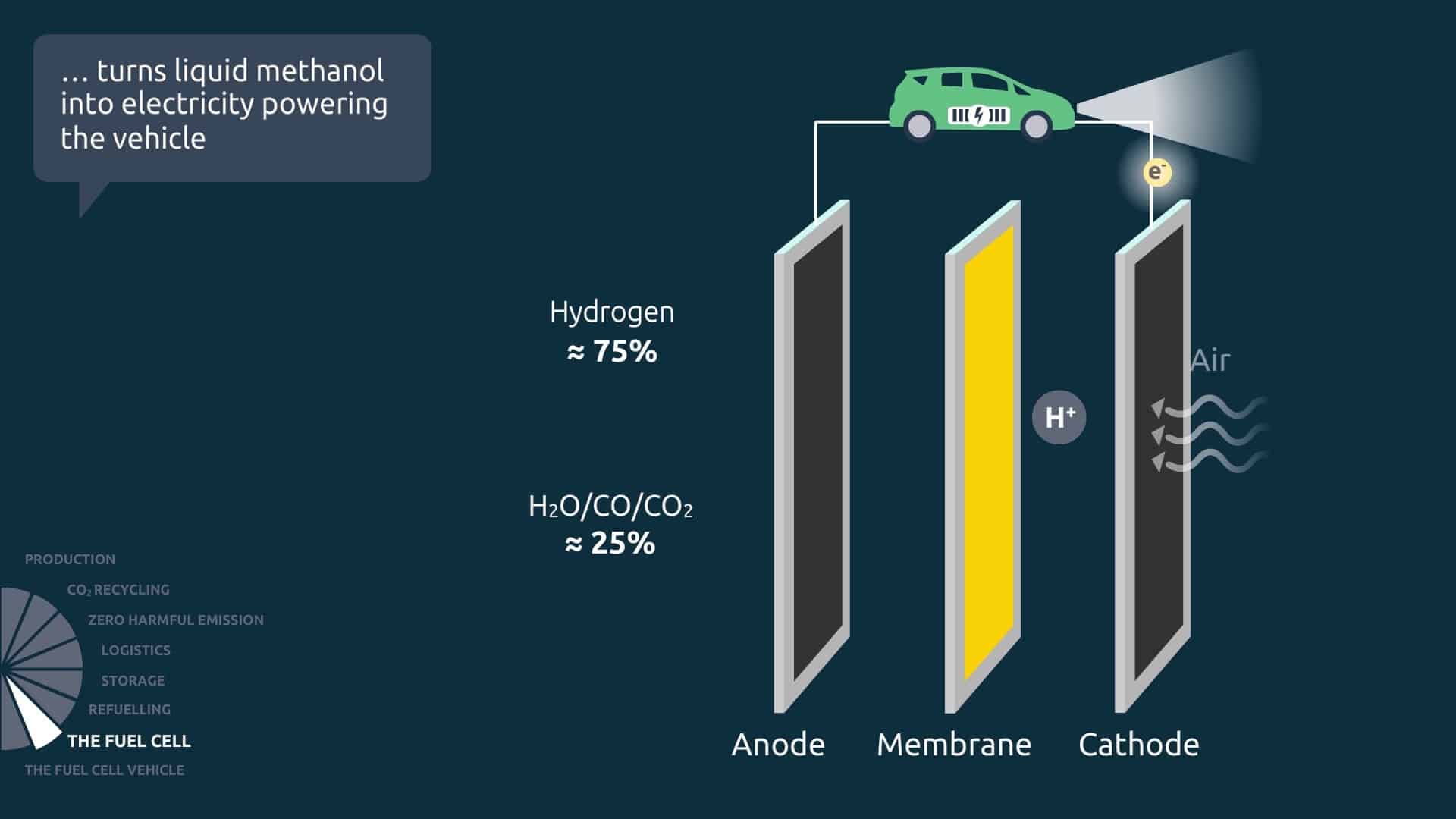

The Blue World Technologies methanol fuel cell consists of several fuel cells that are placed on top of each other in a sandwich construction making a fuel cell stack. Each fuel cell is assembled by a bipolar plate (also called graphite plate, flow plate or separator plate) an MEA (membrane electrode assembly), and another bipolar plate.

The HT PEM-technology operates at 160-180 °C and has a high resistance to impurities in reformat gas which makes it ideal to combine with fuel reformers. The combination can be done without the implementation of expensive and cumbersome clean-up technologies which enables a simple and cost-effective system design.

HT PEM stands for High Temperature Proton Exchange Membrane, and the technology is characterised by simple heat management and a minimum balance of plant components which in turn reduces the parasitic losses to run the system. The simple system design enables a high total system power density.

Methanol reforming

Methanol reforming is a relatively simple process that converts a mix of methanol and water into a hydrogen-rich gas. Before the reforming can take place, the fuel needs to go from liquid to gas form by evaporation, a process that requires energy and in a generic system would mean using primary fuel, leading to lower efficiency. In the combination with HT PEM, the waste heat is of sufficient temperature to drive this process, meaning an energy-free process that leads to superior overall efficiency.

The fundamental chemical process which takes place in the reformer is:

CH3OH + H2O → CO2 + 3 H2

The produced hydrogen (H2) is subsequently used in the fuel cell to produce electricity.

From liquid methanol to electricity

This short explainer animation shows the electrochemical process that turns liquid methanol into electricity that can be used to power a wide range of application.

Interested in learning more about renewable methanol and methanol fuel cells? Watch all the eight steps of the methanol cycle animation by clicking here.

Working at Blue World you will make a difference – for the company, your colleagues, and for the world

The methanol fuel cells provide high energy-efficiency and long lasting durability

The methanol fuel cells act as a green alternative to a wide range of industries around the world